An automatic cotton tissue making machine is a specialized piece of equipment designed to produce cotton tissues or cotton pads. These machines are commonly used in industries such as cosmetics, skincare, and medical fields.

The maximum speed of the whole machine is 120m/min.Stable running speed about 60-100 m/min, *according to the raw materials. Two or four sets of coiling racks for optional (cost effective and efficiently).Fully automatic production line, so as to eliminate the pollution of paper sources and truly meet hygiene standards.

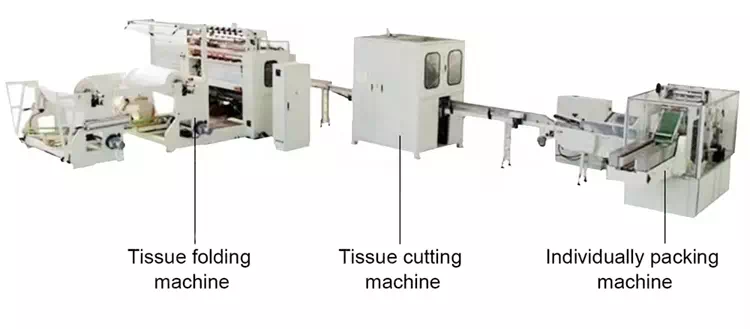

Equipment Structure

Equipment performance description this facial tissue machine adopts large screen true color man-machine interface operation, PLC programming control, Chinese and English one-button switching independent language environment operation;The automatic stacking system adopts "Siemens/ Mitsubishi" full servo drive control to ensure accurate stacking and stable stacking speed of 6~10 lines per minute;

"V" type folding machine: The equipment cuts jumbo rolls of non-woven fabrics and folds them into pieces to facilitate the next process.

| Designing Speed | ≤150 m/min |

|---|---|

| Number of folds | ≤12 fold/min |

| Raw tissue width | ≤1500 mm |

| Raw tissue diameter | 1500 mm |

| Folding type | continuous operation, wind suction folding |

| Breaking Tissue Method | Helicalknife fixed tissue breaking |

| Automatic stacking system | The servo motor is used for independent control torealize automatic stacking function |

| Autoamtic split stack location tracking | Adopt high precision servo encoder |

| Broken tissue detection | with broken towel detection system, the machine stopswhen broken paperoccurs, reducing waste of raw paper |

| Photoeletric detection system | Photoelectric detection is installed on the conveying rack to ensure no collision between semi-finished products |

Tissue cutting machine: Single channel log saw or two lines for optional, cutting the folded non-woven fabric into finished products, to make sure neat and elegant enough before packing.

| The Channel Number | 1,2,3,4 modules |

|---|---|

| Cutting Speed | ≤150 / min |

| Ensure Cutting Accuracy | + / - 1 mm |

| Feed Product Length | ≤5600 mm |

| Cut Length | 85-250 mm |

| Paper Cutting Width | 60-105mm |

| Paper Cutting Height | 50-110 mm |

Individually packing machine: The full-automatic packaging machine packs the cut fabric towels into bags and seals them, and outputs the finished products.

| Maximum roll film diameter | φ600mm |

|---|---|

| Cylinder membrane papercore | φ76-80mm |

| suitable for film thickness | 0.03mm----0.06mm |

| Suitable for pa ckaging film diameter | PEdouble-sided heat sealing film(recommended),all kinds of heat sealing composite film |

| Design working speed | 65Package / min |

| Stable working speed | 50-60 Package / min |

| Overall dimension | 7000mm×1000mm×2200mm(L×W×H) |

| Packing size | L: 100 mm -200 mm(PEmembrane), 100mm -150 mm(composite membrane) W: 70 mm -110 mm H: 30 mm -100 mm |

| Power | 15kw |

| Voltage | AC220 , 50HZ |

Final Product:

Full Automatic Baby Diaper Wipes Production Line With Cotton Tissue and Facial Tissue Making Machine

The equipment is used to produce soft cotton towels, face cleaning towels, etc.Normally size based on 200mm, the width of soft cotton towels can be customized,adjustable by log saw setting.Size can be customized accordingly to local market,we also got marketing research information for reference.

Machine Features:

Fully automatic production line, so as to eliminate the pollution of paper sourcesand truly meet hygiene standards.

Automatic stacking system adopts Siemens/Mitsubishi full servo drive control.Four sets of coiling racks (two for optional) are used for both purposes and standby.When the materials are used up, the equipment automatically prompts to change the cloth.When the folding unit detects a joint, it automatically lifts the knife to prevent the adhesive tape from sticking to the knife stick. Manually or automatically remove joint waste according to settings.

Email:[email protected]

Add: Henan Communication Industry Area, Jingbei 3rd Road, Zhengzhou, Henan, China