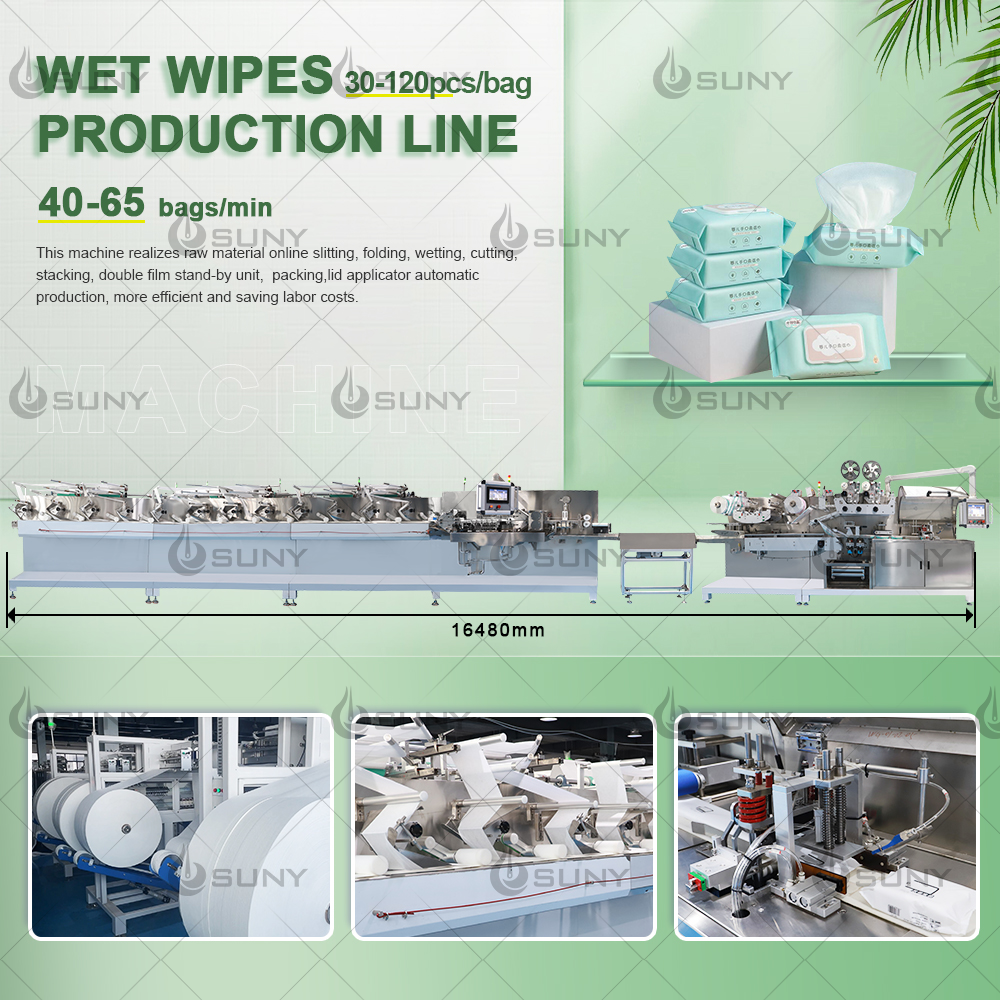

In today's fast-paced world, wet wipes have become an everyday essential — from personal hygiene and baby care to industrial and household cleaning. But have you ever wondered what goes into manufacturing these handy disposable products? If you're planning to enter the booming wet wipes production industry or upgrade your current setup, understanding the wet wipes converting line is crucial.A fully-automated wet wipes converting line is a series of high-precision machines that work together to turn raw materials into finished, packaged wipes

Why Wet Wipes Manufacturing Matters?

According to Statista, the global wet wipes market is projected to reach USD 24.14 billion by 2028, driven by increasing hygiene awareness and consumer convenience. Whether you're producing baby wipes, antibacterial wipes, or makeup remover pads, a reliable and efficient converting line is the backbone of your operations.

What Machines Are Included in a Wet Wipes Converting Line?

1. Raw Material Unwinder

Function:

Feeds the nonwoven fabric into the system.

Unwinds jumbo rolls of nonwoven fabric.

Maintains constant tension to avoid wrinkles or tearing.

Supports multiple lanes for high-speed production.

2. Folding Machine

Function:

Folds the fabric into compact shapes.

Multiple folding styles: Z-fold, N-fold, or customized.

High-speed and precise folding mechanisms.

Adjustable for different product dimensions.

3. Wetting System

Function:

Dispenses the liquid solution onto the folded wipes.

Mixes and sprays the desired wetting formula.

Precise control of liquid volume to ensure consistency.

Optional filtration and UV sterilization systems.

4. Cutting Machine

Function:

Cuts the folded, wetted material into individual wipes.

Equipped with rotary or guillotine cutting systems.

Smooth, sharp cuts reduce fabric waste.

Syncs perfectly with folding and wetting systems.

5. Stacking and Counting System

Function:

Gathers wipes into counted stacks.

Accurate count per package (e.g., 10s, 20s, 80s).

Stack uniformity maintained via sensors and auto adjusters.

Seamless transition to packaging machines.

6. Packaging Machine

Function:

Seals the counted stacks into final packages.

Multiple options: flow wrap, bag packing, canister filling.

Date coding and labeling included.

Compatible with re-sealable lids or stickers.

7. Lid Applicator

Function:

Automatically applies plastic lids onto the wet wipes packages.

Precisely positions and pastes the lid on re-sealable packaging.

Compatible with various lid shapes and sizes.

High-speed robotic arms ensure fast and accurate application.

Often integrated right after the flow wrapping machine.

8. Conveyor Belt System

Function:

Transfers wipes between machines.

Adjustable speeds for different production rates.

Synchronizes all components in the line.

Minimizes manual handling.

9. Date Coder/Printer

Function:

Prints batch codes, expiry dates, or logos.

Thermal inkjet or laser printers.

Works on various surfaces: plastic, foil, nonwoven film.

Integrates easily with packaging equipment.

Building a successful wet wipes production business starts with understanding the core equipment involved. From unwinding raw material to folding, wetting, cutting, stacking, and final packaging — each machine plays a vital role in ensuring high efficiency, product quality, and market competitiveness.

Email:[email protected]

Add: Henan Communication Industry Area, Jingbei 3rd Road, Zhengzhou, Henan, China